Residential Installation

For single homes, installation is simpler:

- Connects directly to the main meter

- Monitors total household consumption

- Detects leaks and waste

GESTAG installation is simple and can be carried out by specialized technicians. The process involves:

You need water meters with pulse output to connect to GESTAG.

The site must have 3G network coverage to transmit data.

A power point close to the installation points.

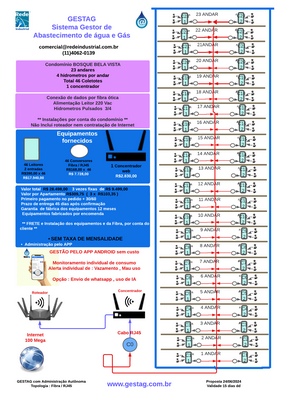

For condominiums, GESTAG can be installed in different ways:

Series connection

Per-floor installation

Steps, benefits, and support — with real equipment images.

For single homes, installation is simpler:

Main practical day-to-day benefits:

Our technical team provides:

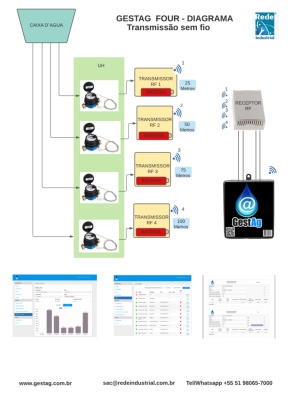

Goal: ensure reliable backhaul between GestAg modules on each floor and the concentrator (router or core switch) using fiber optics — maintaining continuous telemetry, low latency, and an isolated IoT network with security.

How it works: each GestAg (RJ45 port) connects to an RJ45⇄SFP media converter on the floor; fiber runs up/down to the core switch with SFP/SFP+ slots.

How it works: install an L2 switch on each floor with RJ45 ports and 1–2 SFPs. GestAg units connect over copper, and the switch uplink goes over fiber to the core.

How it works: an OLT in the MDF feeds optical splitters in the shaft; on each floor, an ONU delivers RJ45 to local GestAg units.

| Criteria | Converter | L2 Switch | PON |

|---|---|---|---|

| Initial cost | low | medium | high (OLT) / low per ONU |

| Scalability | medium | high | very high |

| Manageability | low | high | medium/high |

| Need for power on the floor | yes | yes | yes |

| Required ducts | 1 fiber per floor | 1 fiber per floor (or ring) | 1 trunk + splitters |

Examples of minimal sets for each architecture:

Always record initial optical levels to track possible future degradation (bends, dirty connectors, or breaks).

Use this space for a video showing fiber pulling, ODF termination, connection to GestAg units on each floor, and real-world building installation examples.

Smart water monitoring with 3G/M2M communication and web dashboards, organized in a clear deployment flow — from the diagnostic phase to project consolidation.